Tsim Cov Ntsiab Lus Ntawm Pob Txha Txhaum Txhaj Pwm

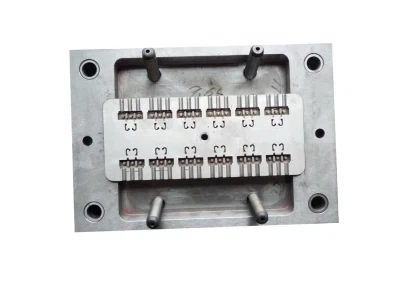

Lub pob tshab vaj huam sib luag txhaj pwm txais PMMA yas txhaj tshuaj molding, PMMA muaj cov yam ntxwv ntawm lub teeb xa hluav taws xob siab, tab sis tsis zoo fluidity, thiab cov txheej txheem txhaj tshuaj molding yog qhov nyuaj. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau them sai sai rau lub pob tshab vaj huam sib luag txhaj pwm tsim thiab kev txhaj tshuaj molding txheej txheem. Kab lus no feem ntau qhia txog cov ntsiab lus tsim ntawm pob tshab vaj huam sib luag txhaj pwm.

1. Txiav txim seb tus naj npawb ntawm cov pwm kab noj hniav raws li qhov loj thiab tuab ntawm cov khoom thiab cov ntim ntim ntawm lub tshuab txhaj tshuaj molding. Lub vaj huam sib luag pob tshab yog qhov sib npaug ntws channel. Feem ntau, ib qho pwm thiab ob kab noj hniav qhib. Thaum qhov loj me me, plaub kab noj hniav tuaj yeem qhib. Yog tias ntau dua 4 kab noj hniav raug qhib, kev ua haujlwm nyuaj ntawm lub tshuab txhaj tshuaj molding yuav raug nce, uas ua rau muaj qhov nce ntawm qhov tsis xws luag.

2. Kev xaiv ntawm qhov chaw parting, vim hais tias cov duab ntawm lub pob tshab vaj huam sib luag yog qhov yooj yim, qhov parting nto feem ntau xaiv raws ntug ntawm cov yas ib feem kom tawm ntawm cov pwm txav ntawm cov yas. Tsis tas li ntawd, nws yog ib qho tsim nyog los xyuas lub kaum sab xis ntawm lub ntug ntawm cov yas, lub kaum sab xis yuav tsum loj txaus, thiab seb puas muaj R me me ntawm qhov sib cais.

3. Kev xaiv ntawm cov kua nplaum pub txoj haujlwm ntawm lub pob tshab vaj huam sib luag txhaj pwm yog qhov tseem ceeb heev. Hauv PMMA pwm, cov pwm ntws channel yuav tsum tau khoov rau hauv S zoo, thiab qhov kawg ntawm cov dej ntws tau tsim nrog cov khoom txias txias ntev, txwv tsis pub nws yooj yim los tsim cov kab cua thiab yaj cov kua nplaum thaum lub sij hawm tsim khoom. taug qab. Qhov loj kawg ntawm kev txhaj tshuaj molded ib feem xaiv lub rooj vag, kom cov yas tuaj yeem yooj yim sau cov kab noj hniav, thiab cov kua nplaum kab ntawm ob lub qhov tsis pom tseeb.

4. Nyob rau hauv kev tsim ntawm lub tso pa tawm txoj hauj lwm, feem ntau lub pob tshab vaj huam sib luag yog tsis pub kom muaj thimble cov cim, yog li ntawd nws yog tsim nyog los qhib lub auxiliary flow channel los pab lub ejection, thiab cov ntws channel no kuj plays lub luag hauj lwm ntawm pa.

5. Kev xaiv cov hlau siv rau pob tshab vaj huam sib luag txhaj pwm. Feem ntau, cov zis tsawg dua 100,000. Japanese NAK80 tuaj yeem siv tau. Yog tias cov zis loj, S136 lossis lwm cov hlau uas muaj kev sib tsoo zoo yuav tsum raug xaiv, kho cua sov rau HRC48-52, thiab tom qab ua tiav polished, tuaj yeem tau txais txiaj ntsig zoo heev.

6. Lub ejection tsim ntawm lub pob tshab vaj huam sib luag pwm. Feem ntau, pob tshab phaj tsis tso cai rau cov tsos ntawm thimble cov cim. Lub ejection ntawm cov yas yog lub ejector tus pin tsim ntawm qhov chaw txhaj tshuaj. Ib tug thimble yog ejected, thiab cov yas tso tawm smoothly.

7. Cua txias system tsim. Pem hauv ntej thiab nram qab pwm ntawm pob tshab vaj huam sib luag txhaj pwm yog tsim los nrog cov tshuab cua txias kom paub meej tias cov txheej txheem tsis tuaj yeem kho tau zoo thaum txhaj tshuaj molding.

8. Lub ntsiab channel ntawm lub pob tshab vaj huam sib luag txhaj pwm yog ntsib cov khoom txias zoo, thiab nws yuav tsum tau tsim nrog Z-shaped rub pas nrig, thiab cov khoom siv rub tawm tsis tuaj yeem siv.