Kev Yuav Tsum Tshwj Xeeb Ntawm Stamping Tuag Rau Stamping Parts.

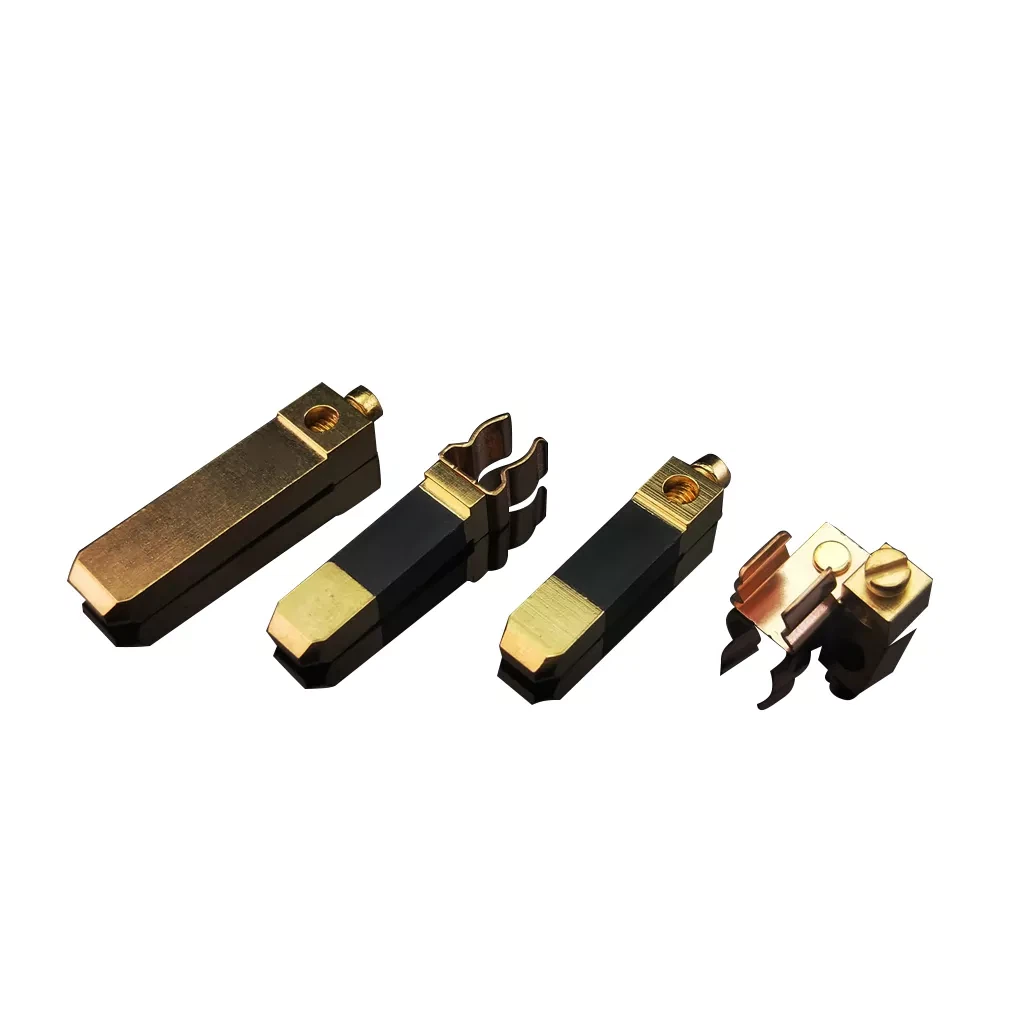

Muaj ntau qhov chaw stamping (hloovlub qhov (socket).thiablub teeb) nyob rau hauv peb cov kev txaus siab

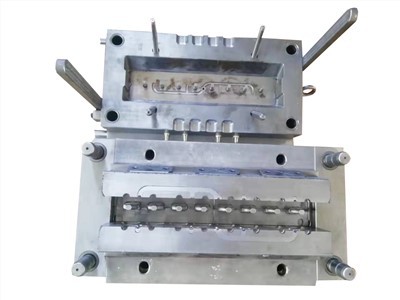

Cov cuab yeej pub mis tsis siv neeg yog ntsia rau ntawm cov hlau stamping tuag los hloov cov phau ntawv pub mis ntawm tus neeg ua haujlwm stamping. Los ntawm kev siv qhov nruam stamping ntawm cov punch zoo tib yam, lub siab ceev tsis siv neeg stamping tuag tuaj yeem ua tiav. Peb hu nws lub automatic feeding stamping tuag. Thaum siv tsis siv neeg pub mis stamping tuag rau tsis siv neeg stamping, feem ntau muaj cov cai tshwj xeeb hauv qab no:

1. Cov hlau yuav tsum siv cov hlau me me los yog cov hlua ntev

Rau kev stamping tuag, feem ntau ntawm peb siv cov ntaub ntawv me me nrog cov ntawv sheared, tab sis yog tias tsis siv neeg pub noj stamping tuag nyob rau hauv high-speed stamping tseem siv cov khoom me me rau stamping, ces cov khoom siv raw yuav tsum tau hloov ntau zaus, yog li nws yog ib qho nyuaj rau exert tsis siv neeg stamping. ntawm high efficiency. Yog li ntawd, tsis siv neeg pub khoom noj stamping tuag yog tsim rau kev siv me me los yog strips ntev (ntau tshaj 10m). Yog hais tias cov khoom yuav raug xa mus yog ib tug semi-tsim dawb paug, thiaj li yuav txhim kho lub stamping efficiency, nws yog tsim nyog los npaj cov khoom ua ntej xa.

2. Yuav tsum muaj cov cuab yeej muab tso rau hauv pwm

Vim qhov raug txwv tsis pub noj cov kauj ruam ntawm cov khoom noj uas txuas nrog pwm, nws tsuas tuaj yeem ncav cuag ±{{0}}.05-± 0.1mm feem ntau. Yog li ntawd, ib tug meej positioning ntaus ntawv yuav tsum tau ntsia rau hauv lub pwm kom precisely txoj hauj lwm ntawm lub feeding kauj ruam ntawm cov khoom noj kom paub meej tias qhov tseeb ntawm cov kauj ruam pub mis raws li qhov yuav tsum tau.

3. Cov khoom pov tseg lossis cov khoom ua haujlwm uas tsim los ntawm stamping yuav tsum tuaj yeem tso tawm

Nyob rau hauv lub nruam stamping lub xeev ntawm cov punch, nws yog tsis yooj yim sua thiab tsis yooj yim sua kom siv phau ntawv tso zis. Txhawm rau kom ntseeg tau tias lub sijhawm tso tawm ntawm cov khoom pov tseg lossis cov khoom ua haujlwm hauv pwm, yuav tsum tau nruab ib lub tshuab tso tawm tsis siv neeg. Tsis tas li ntawd, cov qauv tuag nyob rau hauv qhov tuag yuav tsum muab qhov tseem ceeb rau kev siv qhov qis qis tuag nrog qhov tsis siv neeg ejection.

Tsis siv neeg pub stamping tuag feem ntau muaj cov cai tshwj xeeb hauv qab no

4. Stamping qhov chaw yuav tsum tau tsim nyob rau hauv pwm nyob rau hauv ib lub sij hawm ntau npaum li sai tau

Tom qab lub tshuab pub mis tsis siv neeg txuas nrog lub tshuab stamping tuag, cov nqi tsim khoom ntawm qhov tuag yuav nce. Yog tias cov txheej txheem stamping ib leeg tseem siv, qhov kev ua haujlwm stamping yuav zoo dua. Yog li ntawd, lub stamping qhov chaw yuav tsum tau tsim nyob rau hauv ib lub sij hawm nyob rau hauv ib tug khub ntawm automatic feeding stamping tuag, thiaj li hais tias lub stamping ceev yog siab, uas yuav pab txo tau cov nqi ntawm cov khoom.

5. Qhov kev pub mis yuav tsum ruaj khov