Hlau Stamping Parts kom txo cov seem seem, koj tuaj yeem pib los ntawm cov ntsiab lus no

Thaum feem ntau cov hlau stamping factories txheej txheem stamping qhov chaw, qhov kev tsis lees paub feem ntau yog siab dhau. Tam sim no kev sib tw hauv kev lag luam stamping yog qhov hnyav heev, thiab cov txiaj ntsig tau raug mob hnyav heev. Yog tias tus nqi seem tseem siab, tej zaum yuav tsis tsuas yog tsis muaj txiaj ntsig tom qab kev txiav txim tiav, tab sis kuj yuav poob nyiaj. Nws yog ib qho tseem ceeb tshwj xeeb los daws qhov teeb meem ntawm cov khoom seem ntawm cov hlau stamping qhov chaw.

1. Cov khoom siv raw zoo tsis zoo txaus

Cov ntaub ntawv raw yog thawj qhov kev lees paub rau kev ua cov khoom tsim nyog stamping. Yog hais tias lub hardness thiab nto ntawm cov ntaub ntawv raw tsis ua tau raws li qhov yuav tsum tau zoo, tus coj stamping qhov seem seem yuav twv yuav raug siab heev. Tshwj xeeb tshaj yog rau qee qhov chaw stamping nrog qhov deformation loj, yog tias cov khoom siv tsis tsim nyog, cov kab nrib pleb thiab tawg yuav tshwm sim. Yog li ntawd, thaum yuav cov khoom siv raw, koj yuav tsum tsis txhob khav theeb rau qhov pheej yig, thiab koj yuav tsum nrhiav cov khoom lag luam txhim khu kev qha thiab tsis tu ncua.

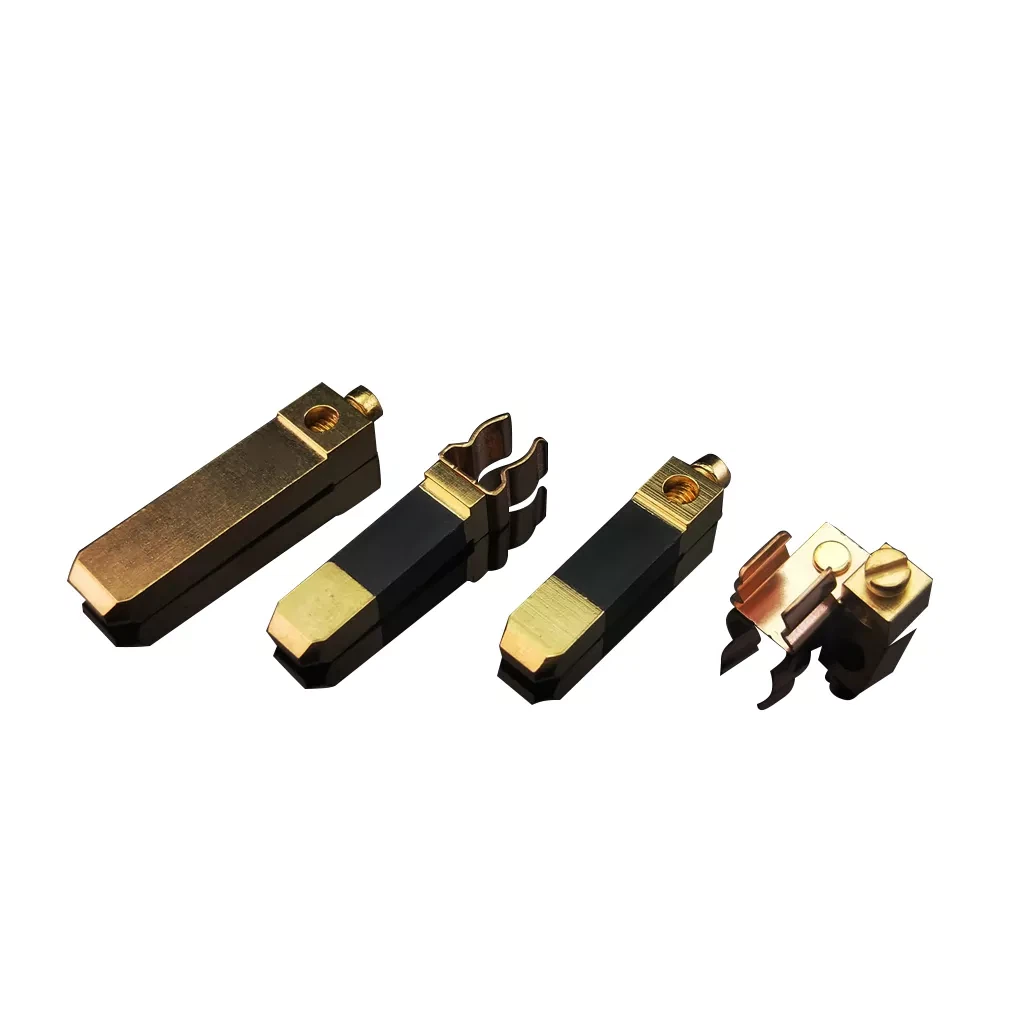

2. Tsis tsim nyog installation ntawm stamping tuag

Lub installation ntawm lub stamping tuag tsis ua raws li cov kev qhia tshwj xeeb, uas ua rau lub cev tsis muaj peev xwm ntawm cov neeg tuag sab sauv thiab cov tuag qis kom koom tes zoo thaum lub sij hawm stamping txheej txheem, uas ua rau muaj kev tsis lees paub ntau. Stamping tuag yog lub hauv paus rau kev ua cov khoom stamping. Kev teeb tsa tseem ceeb heev ntawm qhov chaw uas tsis muaj teeb meem nrog cov tuag. Don' tsis xav tias nws yog ib qho yooj yim rau nruab lub stamping tuag, txawm tias me me yuam kev yuav ua rau lub stamping qhov chaw uas yog scraps. Thaum txhim kho lub stamping tuag, concentricity, clearance, flatness, thiab lwm yam ntawm lub Upper thiab qis tuag tag nrho plays lub luag hauj lwm tseem ceeb.

3. Pwm hnav

Nyob rau hauv lub sij hawm ntev ntawm kev siv cov stamping tuag, hnav los yog xoob fittings yuav ua rau cov khoom yuav tsum scrapped. Muaj ntau lub tuam txhab stamping uas tsis ua raws li niaj hnub tshuaj xyuas thiab kev saib xyuas ntawm cov pwm tom qab cov pwm raug ntsia rau ntau lawm. Tsuas yog thaum lub burr loj heev, cov pwm raug tshem tawm thiab cov riam tsuas yog sharpened. Raws li txhua tus paub, kev hnav ntawm cov pwm tsis yog tsuas yog hnav ntawm riam ntug, tab sis kuj qee qhov pwm yuav hnav nrog kev siv. Tom qab cov khoom no hnav, nws yuav cuam tshuam qhov tseeb ntawm tag nrho cov pwm.

4. Kev ua haujlwm tsis tu ncua ntawm cov neeg ua haujlwm

Cov neeg ua haujlwm tsis ua raws li phau ntawv qhia kev teeb tsa thaum ua haujlwm hauv xovxwm, lossis muaj qhov yuam kev hauv kev pub mis.

5. Cov cuab yeej tso tawm tsis raug

Nyob rau hauv cov txheej txheem pub mis, cov pwm tso cov cuab yeej tsis raug, uas yuav ua rau muaj teeb meem hauv kev sib koom tes ntawm txhua tus txheej txheem, thiab tseem yuav ua rau cov khoom pov tseg.