Xya Qhov Zoo Tshaj Plaws Ntawm Cov Hlau Stamping Tuag Ua Haujlwm

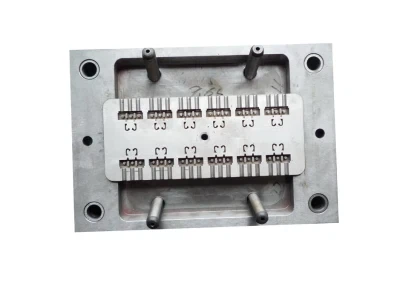

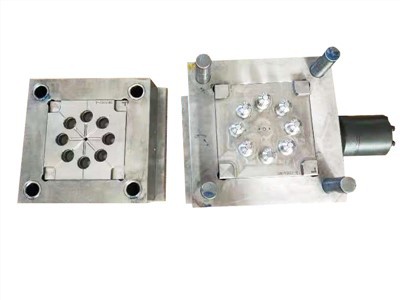

(1) Kev ua haujlwm siab ntau lawm Tus naj npawb ntawm cov khoom lossis cov txheej txheem ua tiav ib lub sijhawm ua haujlwm yog ob peb zaug siab dua li cov txheej txheem kev ua haujlwm dav dav, lossis txawm ntau pua mus rau txhiab zaus. Ntxiv mus, cov txheej txheem hlau stamping kuj tseem siv tau ib qho pwm, ntau qhov chaw, thiab ntau cov txheej txheem cov ntsiab lus ua ke ntawm cov txheej txheem stamping pwm los txhim kho kev tsim khoom.

(2) Cov khoom zoo yog qhov ruaj khov thiab kev sib hloov pauv tau zoo. Cov hlau stamping pwm yog siv los tsim cov khoom, thiab cov yam ntxwv uas cuam tshuam rau cov khoom zoo hloov pauv yog tsawg, thiab cov qib ntawm kev puas tsuaj tsawg. Qee yam tuaj yeem raug kho los ntawm kev siv cov kev ntsuas tsim nyog, kom qhov zoo ntawm cov khoom raug tswj nyob rau hauv qhov zoo tagnrho. Kev ruaj ntseg ntawm cov khoom zoo tuaj yeem ua kom nws qhov kev sib hloov pauv tau zoo. Kev sib hloov zoo yog qhov yooj yim lav rau kev tsim khoom loj ntawm cov kab sib dhos. Nyob rau tib lub sijhawm, nws kuj yog qhov tsim nyog rau cov khoom tu thiab hloov pauv.

(3) Kev siv cov khoom siv yog siab. Los ntawm cov txheej txheem sib txawv, xws li: ntoo khaub lig, kab pheeb ces kaum, ntau kab, sib xyaw, nested, thiab txawm tias tsis muaj pov tseg layout txoj kev, nws tuaj yeem txhim kho qhov kev siv ntawm cov khoom siv thiab txo cov nqi ntawm cov khoom. .

(4) Cov khoom siv tsis tas yuav tsum tau ua kom sov. Raws li ib txwm muaj, cov khoom siv tsis tas yuav tsum tau rhuab thaum lub sijhawm ua haujlwm stamping. Qhov no tsis tsuas yog txuag lub zog, txo cov khoom siv cua sov thiab chaw ua haujlwm, tab sis kuj zam cov duab thiab qhov loj me tsis ruaj khov los ntawm qhov chaw oxidation, kub hnyiab, thiab deformation ntawm cov khoom los ntawm cua sov. Nws tseem tuaj yeem tiv thaiv qhov tsis zoo ntawm qhov kub thiab txias ntawm cov pwm.

(5) Cov cuab yeej cuab tam ntawm cov khoom stamping tau raug txhim kho. Kev cuam tshuam los ntawm qhov tshwm sim hardening ntawm hlau stamping, cov qauv saum npoo ntawm cov khoom stamping yog nruj, lub hardness thiab hnav tsis kam yog nce, thiab lub zog thiab rigidity ntawm cov stamping qhov chaw kuj tseem txhim kho.

(6) Muaj ntau hom kev siv. Muaj ntau yam khoom tsim nyog rau stamping. Nws tuaj yeem daws tau ntau yam txheej txheem uas ua tsis tau lossis nyuaj ua kom tiav los ntawm kev siv tshuab ua haujlwm, tshwj xeeb tshaj yog rau kev ua thiab tsim ntawm qee qhov nyias, mos, nyuaj, coj txawv txawv, micro qhov chaw, lossis cov khoom tsis yog xim hlau. Hlau stamping txoj kev yog ib qho kev ua kom muaj zog thiab tsim txoj kev.

(7) Kev ua haujlwm yooj yim thiab kev siv zog ntawm cov neeg ua haujlwm tsawg. Cov txheej txheem tsim thiab cov khoom zoo ntawm cov khoom feem ntau tau lees paub los ntawm cov pwm thiab cov khoom siv stamping. Cov kev nqis tes ua thaum lub sijhawm ua haujlwm yog tib yam thiab tsis cuam tshuam los ntawm qhov nyuaj ntawm cov khoom. Cov neeg ua haujlwm xav tau qee yam kev cai thiab raug cob qhia ntawm txoj haujlwm ua ntej lawv tuaj yeem pib ua haujlwm.